Fiberglass Rebar

FRP(Fiberglass Reinforced Plastic) composite rebar is made of high strength glass fibers along with an extremely durable resin, a perfect replacement of steel rebar.We offer 5 product series as below: standard FRP polyster rebar,standard FRP polyster anchor bolt,frp epoxy rebar, frp hollow grounting polyster rebar and frp tray plate.

Standard FRP Polyster Rebar

| Nominal Diameter | Nominal Area | Tensile Strength | |||

| Size | mm | in | mm ² | in ² | MPa |

| 2 | 6 | 1/4 | 31.67 | 0.049 | 896 |

| 3 | 10 | 3/8 | 71.26 | 0.110 | 827 |

| 4 | 13 | 1/2 | 126.7 | 0.196 | 758 |

| 5 | 16 | 5/8 | 197.9 | 0.307 | 724 |

| 6 | 19 | 3/4 | 285.0 | 0.442 | 690 |

| 7 | 22 | 7/8 | 387.9 | 0.601 | 655 |

| 8 | 25 | 1 | 506.7 | 0.785 | 620 |

| 9 | 29 | 1-1/8 | 641.3 | 0.994 | 586 |

| 10 | 32 | 1-1/4 | 791.7 | 1.227 | 551 |

Standard FRP Polyster Anchor Bolts

Diameter Available:5/8inch,3/4inch,7/8inch,1inch...

FRP Epoxy Rebar

Diameter Available:1/2inch,3/4inch,3/8inch,1inch...

FRP Hollow Grouting Polyster Bolt

Outside Diameter :7/8inch,1inch,1-1/8inch,...

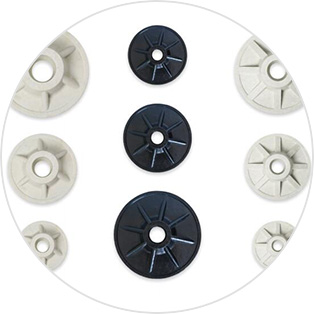

FRP Tray Plate

We customize to your request.

Applications :

- Coal mine roadway

- Temporary support

- Subway tunnel

- Slope support

- Rock support

- Seawall

- Building construction

- Mining and so on.

Advantages:

Non-Corrosive: to expose to a wide variety of corrosive elements including chloride ions.

High Strength-to-Weight Ratio: good reinforcement in weight sensitive applications.

Non-Conductive: excellent electrical and thermal insulation.

Excellent Impact Resistance: resist sudden and severe point loading.

Magnetic Transparency: not affected by electromagnetic fields.

Bendable:Transparency: easy to be bended and transported

High Strength-to-Weight Ratio: good reinforcement in weight sensitive applications.

Non-Conductive: excellent electrical and thermal insulation.

Excellent Impact Resistance: resist sudden and severe point loading.

Magnetic Transparency: not affected by electromagnetic fields.

Bendable:Transparency: easy to be bended and transported

*For a 5 to 7 percent greater cost in project materials, you achieve 10 to 20 years longer life for the structure with this product."

www.ecopultrusions.com

ReplyDelete

ReplyDeleteThank you so much for taking time to read my blog. I read all my comments and appreciate each and every one!

FRP Manufacturers in Chennai