Fiberglass Cable Tray and Cable Ladder, FRP Strut

Cable Protection System

FRP cable protection sytem supplied by Eco Pultrusions is made by fiberglass with polyester resin or vinylester resin. Product Ranges include basically frp cable tray system, frp cable ladder system, wire mesh cable tray system, frp cable trunking sytem, pole riser guard

Techinical Data Of Frp Cable Tray System

1. Normal products of Pultrusion

| Name | Flexural strength (Mpa) | Punch strength (KJ/m²) | Density (Kg/m) | 25% H2SO4 Resistance (g/m²) | 30%HCL Resistance (g/m²) | 5% NaOH Resistance (g/m²) | Life cycle |

| Technical data | 180 | 90 | 1.7~2.0 | ±2 | ±2 | ±2.5 | ≥20 years |

| Remarks | / | / | / | Dipped in for 24h | Dipped in 24h | Dipped in for 24h | / |

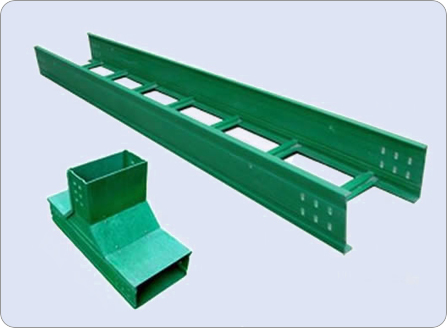

Frp cable ladder system

Standard Dimension:

Height: 100 mm

Width: 200, 300, 400, 500, 600, 800 mm

Standard Length: 3 meter, 6 meter

Height: 100 mm

Width: 200, 300, 400, 500, 600, 800 mm

Standard Length: 3 meter, 6 meter

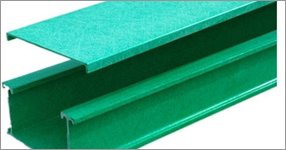

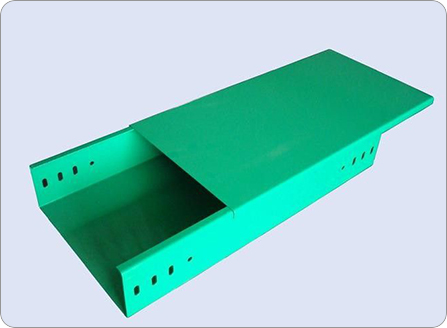

frp cable trunking sytem

SSpecification(mm)

Width*Height

50*25 100*50 150*75 200*100 250*125

300*150 400*200 500*200 600*200 800*200

Width*Height

50*25 100*50 150*75 200*100 250*125

300*150 400*200 500*200 600*200 800*200

Pole Riser Guard

Pole riser guard also called U guard, is used to protect utility supplies on walls ie, gas, oil, water and fibre optic runs, satellite and cable tv, telecom wires, etc.

| U pole riser guard | ||||

| Code name | Width | Height | Length | Unit weight (kg/ft) |

| UG-01 | 1.79" | 1.67" | 5ft/8ft/10ft | 0.15 |

| UG-02 | 2.05" | 2.24" | 5ft/8ft/10ft | 0.21 |

| UG-03 | 3" | 3.19" | 5ft/8ft/10ft | 0.33 |

| UG-04 | 3.82" | 3.94" | 5ft/8ft/10ft | 0.44 |

Frp Cable Tray Uses

- City grid construction project

- Telecom and cable lines project

- Super speed way and bridge construction project

- City foundation project

- Airport and sport ground

- Cable under sea or river

- Industry zone and communities

Frp Cable Tray Features

- Light weight

- High durability

- Fire retardant

- Easy to install

- Anti corrosion

- High load bearing

- Good electrical insulation

- Low thermal conductivity

www.ecopultrusions.com

ReplyDeleteThe types of cables, allowed in cable trays, and the wiring methods permitted in cable trays can be found in NEC Section 392.10 (A). This Section also lists various corresponding NEC Articles which describe the conditions of use and installation requirements for a particular class or type of cable. Additional considerations such as fill capacity, allowable ampacity, cable splicing within trays, and securing and supporting cables are addressed in Article 392. Users should be familiar with all these Articles and check the manufacturer’s specifications, to verify selected cables meet all application requirements and NEC requirements.Cable Tray

ReplyDeletecable tray fabricated from mild steel and dip in the hot zinc for rusting as per atmosphere condition some time we use stainless steel or aluminum of fiber glass selection of material depends on area condition we can install the cable tray at structure with the walls of hang from roof with the help of rods some time we use the cover at tray to protect the cables from sun light cable tray is the part of electrical installation perforation in the cable tray help out to exhaust the heat of power cable due to ventilation we can reduce the cable temperatureCable Tray

ReplyDelete