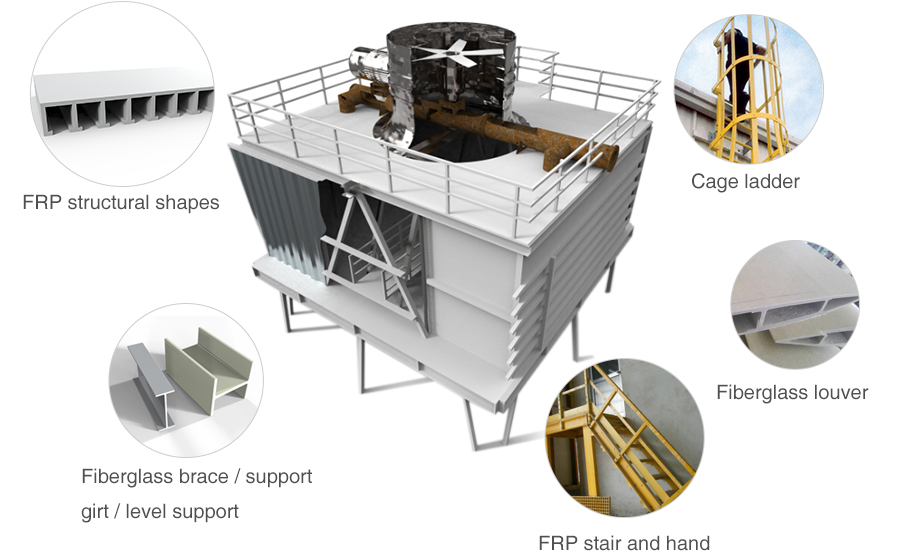

FRP Cooling Tower, fiberglass components

Cooling towers function to discharge waste heat from an industrial process into the atmosphere, and are essential for large energy-producing plants. The use of FRP in the cooling tower market is growing fast. Pultruded FRP is recognized as the best structural components for cooling tower construction. Eco Pultrusions is committed to making a larger cooling tower market with its standard pultruded FRP shapes and custom ones, with features:

- Light weight, high strength

- Simple and quick erection

- Corrosion and rot resistance

- More cost competitive

- Flexible and innovative design

- Lower maintenance

- Longer service time

Fiberglass Cooling Tower Components

Applications

There are three main types of cooling towers that are defined by how water or air pass through them. These types include crossflow, counterflow, and hyperbolic. Standard FRP pultruded profiles and custom profiles from Eco Pultrusions are universal for all the three types of the cooling towers. Square tubes function as buttom column at perimeter for louvres, mid level for header support or buttom column internal etc. Channel functions as transverset girt ,longitudinal girt or stair platform landing support girts etc. I beam as fill level support or fan deck level support, Toe Plate as kick board; Access platform, catwalk or an FRP walkway also requires FRP pultruded profiles, standard or custom profiles.

For more information, please visit www.ecopultrusions.com or contact ivy@ecopultrusions.com

ReplyDelete